world class manufacturing pillars

Cassino Italy A World Class Sustainable Plant The harmonious interaction between people technology innovation and the Environment all contribute to making the Cassino assembly plant a model of world-class excellence. WCM is a mindset based on a continuous improvement approach 2 What is TPM.

People Development A Critical Pillar In World Class Manufacturing

Their focus on driving the organization towards becoming a lean mean machine with cost-effective and flexible operating processes.

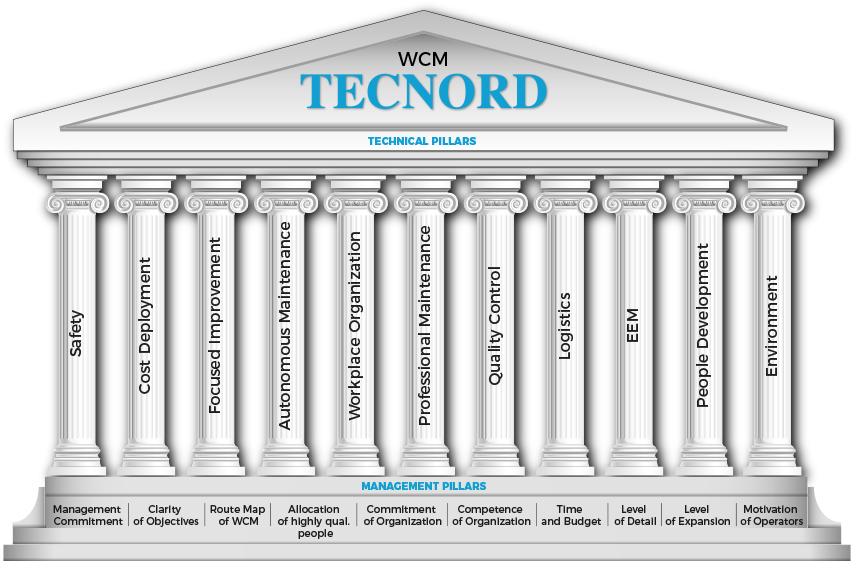

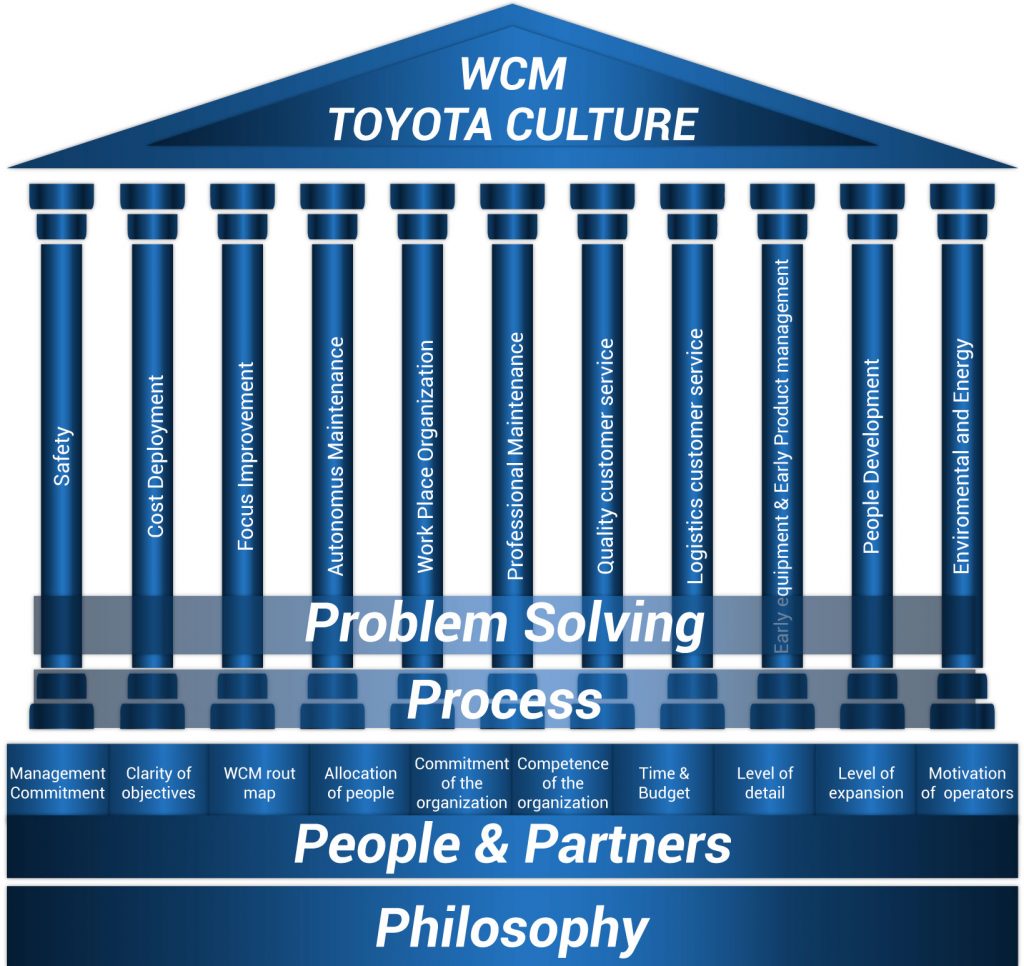

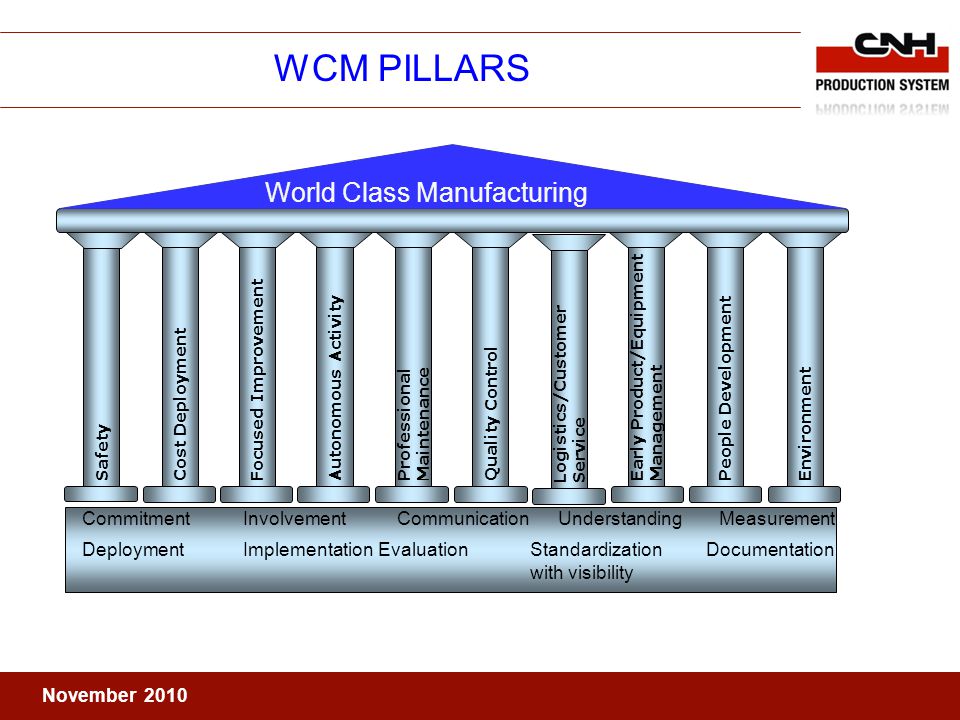

. Autonomous maintenance and workplace organization 5. 1 Safety Occupational safety 2 Cost Deployment Distribution of Costs 3 Focused Improvement 4a Autonomous Maintenance 4b Workplace Organization 5 Professional maintenance 6 Quality Control 7 Logistics Customer Service 8 Early equipment Management 9 People Development. This is why many companies worldwide have embraced World Class Manufacturing WCM - an integrated approach to continuously improving all aspects of production performance in all areas of the production system represented by the 10 pillars of WCM from cost deployment to people development.

With a team of extremely dedicated and quality lecturers world class manufacturing pillars yamashina will not only be a place to share knowledge but also to help students get inspired to explore and discover many. World class manufacturing is a process driven approach where various techniques and philosophy are used in one combination or other. 3 - Established and efficient reliability and maintenance programs.

AERO CHIP was established in 1986 in Compton CA and is a growth-oriented organization engaged in manufacturing of components for military and commercial aerospace. TPM WCM Zero BDs Zero Defect and Zero Accident. What is World Class Manufacturing.

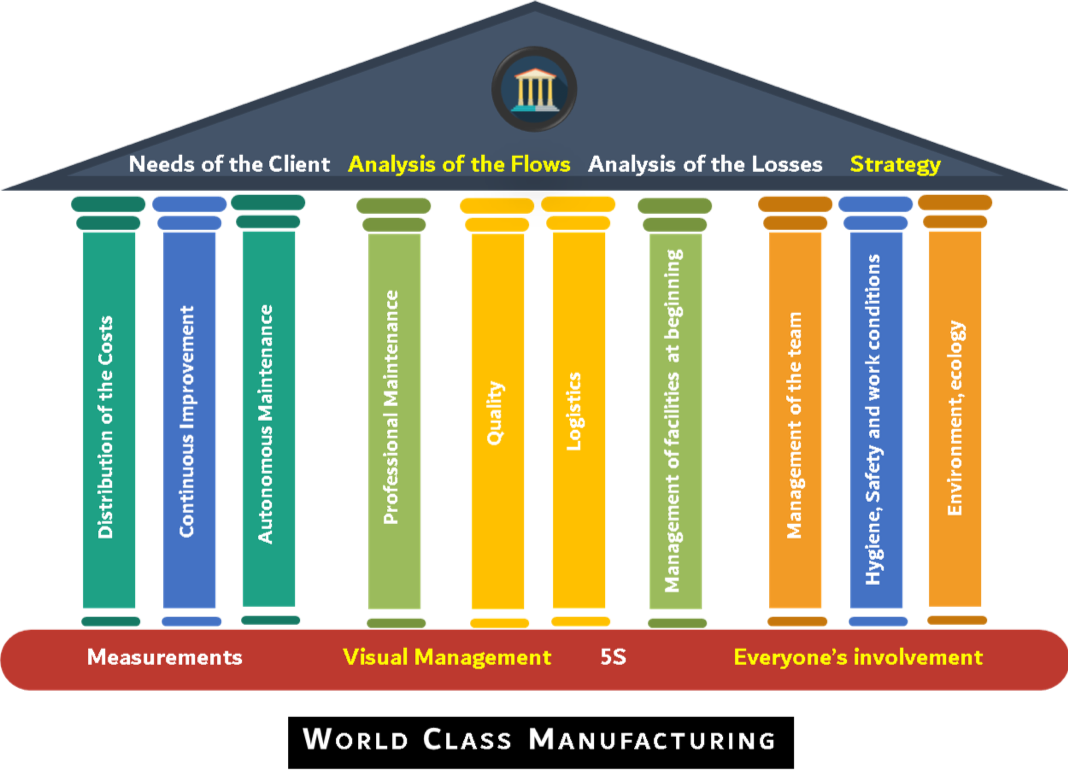

The ten technical pillars are. A struc tured and integrated production system that encompasses all the processes of the plant the security environment from maintenance to logistics and quality. Here below in Table 11 features for each technical pillars are illustrated.

World class manufacturing pillars yamashina provides a comprehensive and comprehensive pathway for students to see progress after the end of each module. It is inferred that to address all the components of the manufacturing system the following tools are necessary see Table 12. According to Fiat Group Automobiles World Class Manufacturing WCM is.

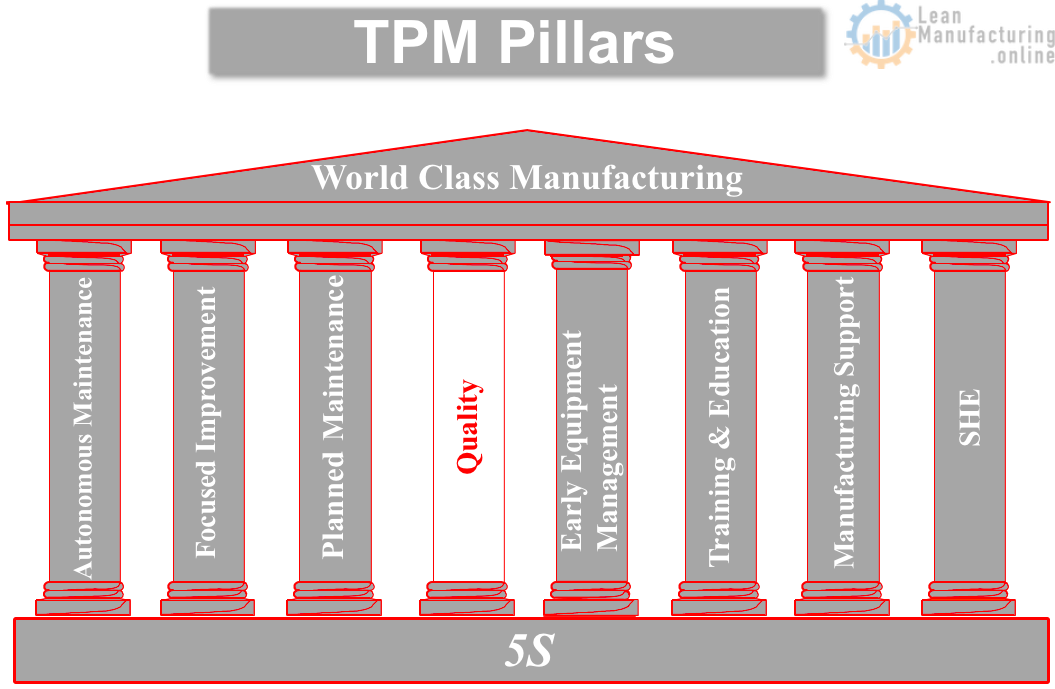

Developed by JIPM A System emphasizing complete Care Maintaining of machines delivered dramatic results. This pillar is why most manufacturing facilities fall short. In 2014 14277 projects were implemented within WCM generating savings of 1956 million.

Both require an unwavering commitment to excellence and continuous improvement from every member of the organisation. Make-to-order streamlined flow small lot sizes families of parts doing it right the first time cellular manufacturing total productive maintenance quick changeover zero defects just-in-time variability reduction high employee involvement cross. World class manufacturing usually involves implementation of the following.

Reliability culture is the most elusive and most important pillar to achieve World Class reliability. World class components for the aerospace industry. In this concept one of the nine pillars is directly related to the quality and.

Make to order Streamlined Flow Smaller lot sizes Collection of parts Doing it right first time Cellular or group manufacturing Total preventive maintenance Quick replacement. At CNH Industrial the use of tools for sharing information and collecting suggestions is well established. Early equipment management 9.

3 days ago According to Gunn 1987 World-Class manufacturing rests on three pillars namely Computer integrated manufacturing CIM total quality control TQC and just-in-time JIT production methods. The Technical pillars of World Class Manufacturing. Pillars of the WCM The 10 technical pillars of World Class Manufacturing are.

World Class Manufacturing WCM is a set of concepts set out as policies and principles developed for the operation and management of a manufacturing organization. Thus from literature survey it is inferred that it is not possible to use the specific single tool to achieve world-class performance and address all the manufacturing components. Admittedly there are fewer giant bottles of champagne when Manufacturing.

T otal P roductive M aintenance Origins. The WCM system is made up of ten technical- and ten managerial pillars illustrated as a temple see below. Some of the techniques are as follows.

Safety Cost Deployment Focused improvement Autonomous maintenance and workplace organization Professional maintenance Quality control Logistics Customer service Early equipment management People development Environment. The World Class Manufacturing WCM is a contemporary concept that is applied by the world leaders in the business. Read more 1 2 3 We use website cookies.

In 2014 about 395 thousand suggestions were collected across the plants where WCM principles are applied with an average of 11 per employee. As we explored last time the process of becoming a World Class Manufacturing WCM organisation is similar to becoming a World Class F1 winning team. The ten technical pillars are as follows.

The ten pillars of World Class Manufacturing More. Logistics Customer service 8.

Eight Pillars Of Total Productive Maintenance 5s Foundation World Class Manufacturing Roof Quality Continuously Improving Manufacturing

World Class Manufacturing Or Wcm What Is It

Wcm Pillars Description And Features Business Building Information

Oem Wcm World Class Manufacturing Alfra Lean Advisors

Illustrates The Ten Pillars Of Wcm Download Scientific Diagram

The 7 Pillars Of World Class Organisations Youtube

World Class Manufacturing Pillars Download Scientific Diagram

November 2010 Wcm Pillars World Class Manufacturing Cost Deployment Autonomous Activity Professionalmaintenancequality Controllogistics Customerserviceearly Ppt Download

World Class Manufacturing Andrzej Ryszard Mroz 1 Updates Research Project

World Class Manufacturing Wcm Model And Operational Performance Indicators Comparison Between Wcm Firms Semantic Scholar

Robert Becklin Operations Supervisor Emerson Linkedin

World Class Manufacturing Or Wcm What Is It

10 Steps To Achieve World Class Manufacturing Maintenance Practices M A N O X B L O G

6s A Solid Rock In World Class Manufacturing

10 Pillars Of World Class Manufacturing Visit Us For 100 Operational Excellence Presentation U Nikunjbhoraniya

Pillars Description And Features Open Textbooks For Hong Kong

The World Class Manufacturing Programme At Chrysler Fiat Co Better Operations